H Beams are an integral part of modern construction, widely used in buildings, bridges, and industrial frameworks. Their strength, durability, and versatility make them a preferred choice for architects and engineers. However, the performance of H Beams depends heavily on their quality. Understanding the factors that determine the quality of H Beams is essential for ensuring safe and long-lasting structures. This article explores the key aspects that influence the quality of H Beams and provides guidance for selecting the right beams for construction projects.

Understanding H Beams and Their Importance in Construction

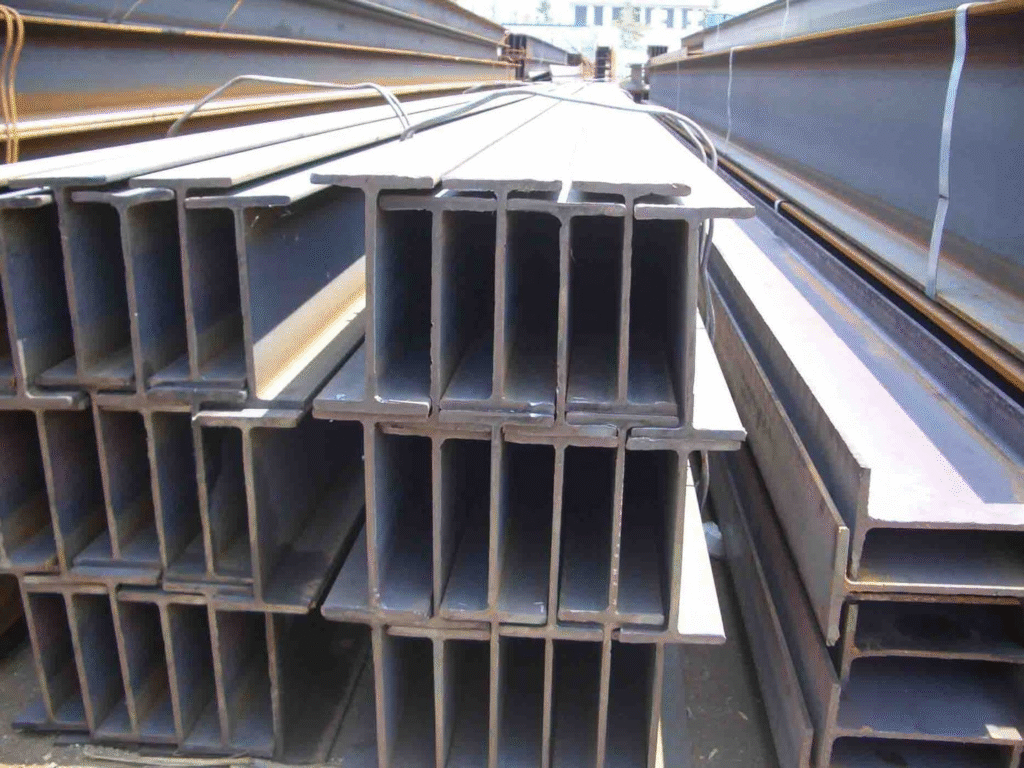

H Beams, also known as I-beams due to their cross-sectional shape resembling the letter “H,” are steel beams designed to bear heavy loads. Their structural design allows them to provide exceptional support while minimizing material usage, making them cost-effective and efficient. H Beams are primarily used in construction projects for:

- Supporting frameworks of buildings

- Bridges and flyovers

- Industrial structures and warehouses

- Large-scale residential and commercial constructions

The quality of H Beams directly impacts the safety and longevity of the structures in which they are used. Using substandard H Beams can lead to structural weaknesses, safety hazards, and costly repairs. Therefore, it is crucial to understand the factors that determine their quality before selection.

NOTE: H Beams were sourced from top-grade steel, ensuring durability and strength for heavy construction projects. SYDNEY METAL TRADING LLC provided these high-quality H Beams, meeting industry standards and client requirements.

Material Composition of H Beams

The first and foremost factor influencing the quality of H Beams is the steel material used in their manufacturing. High-quality H Beams are typically made from carbon steel, alloy steel, or other high-grade steel materials that offer excellent strength and durability. The composition of steel determines the beam’s resistance to bending, stress, and corrosion.

Steel with higher carbon content provides greater strength but may be less ductile, while alloy steel offers enhanced resistance to wear, corrosion, and environmental factors. The use of low-grade steel or improper alloys can compromise the beam’s performance, making it unsuitable for heavy construction applications. Therefore, verifying the steel grade and certifications from manufacturers is critical when purchasing H Beams.

Manufacturing Process and Techniques

The manufacturing process is another key factor that determines the quality of H Beams. Modern H Beams are produced using two main methods: hot rolling and welding.

Hot Rolled H Beams

Hot rolling involves heating steel to high temperatures and shaping it into the desired beam profile. This method ensures uniform strength and structural integrity across the entire beam. Hot rolled H Beams are highly durable and can withstand heavy loads and harsh environmental conditions.

Welded H Beams

Welded H Beams are created by welding steel plates together to form the H-shaped cross-section. While this method allows for customization and cost reduction, the quality of welded beams depends heavily on the welding process. Poor welding can create weak points, leading to potential structural failures. Proper quality control and adherence to international welding standards are essential for ensuring the reliability of welded H Beams.

Dimensional Accuracy and Structural Integrity

The quality of H Beams is also determined by their dimensional accuracy. Consistent dimensions, including flange width, web thickness, and overall length, are crucial for proper load distribution and structural stability. Variations in dimensions can lead to uneven stress distribution, reducing the beam’s load-bearing capacity.

Structural integrity is further influenced by the straightness of the beam and the absence of defects such as cracks, twists, or warping. Quality H Beams should maintain uniformity in shape and dimensions throughout their length to ensure seamless integration into construction projects.

Surface Quality and Coating

The surface quality of H Beams plays a significant role in determining their durability and longevity. Beams with rough surfaces, rust, or surface cracks are prone to corrosion and structural weakening. High-quality H Beams undergo surface treatments such as sandblasting, galvanization, or coating with anti-corrosive paint to protect against environmental damage.

Surface coatings not only enhance the appearance of H Beams but also provide a protective layer against moisture, chemicals, and extreme weather conditions. Choosing H Beams with proper surface treatment ensures long-term performance and reduces maintenance costs.

Mechanical Properties and Load-Bearing Capacity

H Beams are primarily designed to bear heavy loads, so their mechanical properties are critical indicators of quality. Key mechanical properties include tensile strength, yield strength, and elongation. Tensile strength refers to the beam’s ability to withstand stretching forces, while yield strength indicates the maximum stress the beam can endure without permanent deformation. Elongation measures the beam’s ability to flex without breaking.

High-quality H Beams should meet or exceed industry standards for mechanical properties. Engineers and construction professionals must verify these properties through material testing and certification to ensure the beams can handle the intended loads safely.

Compliance with Industry Standards

Compliance with international and regional standards is a vital factor in determining the quality of H Beams. Standards such as ASTM, EN, and ISO define the minimum requirements for material composition, mechanical properties, dimensions, and manufacturing processes. Beams that adhere to these standards provide assurance of reliability, performance, and safety.

Purchasing H Beams from certified manufacturers or suppliers who provide quality assurance documentation ensures that the beams meet industry regulations and are suitable for structural applications.

Environmental and Usage Considerations

The quality of H Beams is also influenced by the environment in which they are used. Beams exposed to harsh climates, high humidity, or industrial chemicals require additional protection to prevent corrosion and degradation. Environmental considerations such as load type, frequency, and exposure to vibrations must be evaluated when selecting H Beams for specific projects.

High-quality H Beams designed for specialized applications, such as marine or industrial environments, may incorporate additional features like thicker coatings or corrosion-resistant alloys to enhance performance and longevity.

Testing and Quality Control Measures

Testing and quality control are essential components of ensuring H Beam quality. Reputable manufacturers conduct rigorous testing, including ultrasonic testing, radiographic inspection, and mechanical property analysis, to detect defects and verify compliance with standards.

Quality control measures during production include monitoring steel composition, maintaining proper temperature control during rolling or welding, and performing visual inspections for surface defects. Proper testing and quality control ensure that H Beams perform reliably under load and meet safety requirements.

Cost Considerations and Value for Money

While cost is an important factor in construction projects, it should not compromise the quality of H Beams. High-quality beams may come at a higher price but provide long-term durability, reduced maintenance, and enhanced structural safety. Investing in substandard or cheap H Beams may result in structural issues, higher repair costs, and safety hazards.

Evaluating the cost-to-benefit ratio and prioritizing quality over price ensures that construction projects achieve optimal safety, performance, and longevity.

Conclusion

H Beams play a critical role in modern construction, providing strength, stability, and support for various structures. The quality of H Beams determines their effectiveness and longevity, making it essential to consider multiple factors before selection. Material composition, manufacturing process, dimensional accuracy, surface quality, mechanical properties, compliance with industry standards, environmental considerations, and rigorous testing all contribute to the overall quality of H Beams in use.

Choosing high-quality H Beams from certified suppliers ensures the safety, durability, and efficiency of construction projects. By understanding and prioritizing these factors, engineers, architects, and construction professionals can make informed decisions and build structures that stand the test of time.