ABC cable, also known as Aerial Bundled Cable, is a modern and efficient alternative to conventional bare overhead conductors. It is designed for power distribution systems where reliability, safety, and reduced maintenance are crucial. HNBF Power, a leading manufacturer of overhead conductors and power cables, produces ABC cable engineered for exceptional mechanical strength, electrical performance, and environmental durability.

This guide explores the construction, advantages, applications, and specifications of ABC cables to help engineers, project managers, and procurement professionals make informed decisions for their next power infrastructure project.

What Is an ABC Cable?

An ABC cable (Aerial Bundled Cable) consists of multiple insulated phase conductors bundled tightly together, typically with a neutral messenger conductor made of aluminum alloy or steel-reinforced aluminum. Unlike traditional bare conductors, the insulation provides additional protection against short circuits and external damage, making ABC cables ideal for densely populated areas and regions with harsh weather conditions.

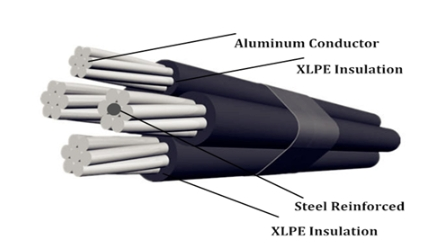

Typical construction of ABC cable includes:

- Phase Conductors: Aluminum or aluminum alloy.

- Insulation: Cross-linked polyethylene (XLPE) or polyethylene (PE).

- Messenger Wire: Bare or insulated neutral conductor (can be steel-reinforced).

Key Advantages of ABC Cable

1. Improved Safety

The insulated design minimizes the risk of accidental electrocution, short circuits, or line faults due to contact with trees or buildings.

2. Reduced Maintenance

ABC cables require less maintenance than traditional bare overhead conductors because they are less prone to line faults, corrosion, or snapping caused by wind and debris.

3. Cost-Effective Installation

Installation is faster and more economical since ABC cables can be strung on poles without extensive cross-arm structures. They also reduce the need for costly tree trimming.

4. Superior Electrical Performance

With lower line losses and better voltage regulation, ABC cables provide efficient power distribution for both urban and rural networks.

5. Enhanced Durability

Designed to withstand UV exposure, moisture, heat, and environmental stress, ABC cables ensure long-term stability and consistent performance in various climates.

Common Applications of ABC Cables

ABC cables are widely used in both low- and medium-voltage distribution networks. Some common applications include:

- Urban and suburban overhead power distribution systems

- Rural electrification projects

- Temporary power supply lines

- Areas with narrow streets or dense vegetation

- Service connections to residential and commercial buildings

HNBF Power’s ABC cables are designed to meet the demanding standards of national and international power utilities, ensuring long-lasting and safe power transmission.

Technical Specifications of HNBF Power ABC Cable

HNBF Power manufactures ABC cables that comply with IEC, ASTM, BS, and other international standards. The following characteristics define their high-quality performance:

| Parameter | Specification |

|---|---|

| Conductor Material | Aluminum / Aluminum Alloy |

| Insulation Material | XLPE / PE |

| Voltage Range | 0.6/1 kV to 33 kV |

| Messenger Wire | Aluminum Alloy / ACSR |

| Temperature Rating | Up to 90°C (continuous operation) |

| Standards | IEC 60502, BS 7870, ASTM B231 |

These technical parameters make HNBF Power’s ABC cables suitable for a wide range of electrical distribution networks, providing both mechanical stability and electrical efficiency.

Why Choose HNBF Power as Your ABC Cable Manufacturer

HNBF Power brings decades of experience in producing high-performance conductors and cables for the global power industry. Their ABC cables are manufactured under strict quality management systems, ensuring reliability and compliance with all international standards.

Key differentiators include:

- Advanced production lines and testing facilities

- Consistent quality control and certification compliance

- Custom design capabilities for specific voltage and installation needs

- Technical support and supply solutions for large-scale projects

By partnering with HNBF Power, utilities and contractors gain access to durable, efficient, and cost-effective aerial bundled cable systems designed to perform even under challenging field conditions.

Frequently Asked Questions (FAQs)

1. What is the main difference between ABC cable and ACSR conductor?

ABC cable is insulated, making it safer and more suitable for densely populated or vegetation-rich areas, while ACSR is a bare conductor used mainly for high-voltage transmission lines.

2. Can ABC cables be installed underground?

No. ABC cables are specifically designed for aerial installations. For underground systems, armored or XLPE-insulated power cables are recommended.

3. What voltage levels are available for ABC cables?

HNBF Power manufactures ABC cables in voltage ranges from 0.6/1 kV up to 33 kV to meet various distribution system requirements.

4. How long does an ABC cable last?

With proper installation and maintenance, high-quality ABC cables can last over 30 years, depending on environmental conditions and load.

5. Are ABC cables suitable for coastal or high-humidity areas?

Yes. The insulated design and corrosion-resistant materials make them ideal for coastal regions and humid environments.

Conclusion

ABC cables offer a modern, safe, and efficient solution for overhead power distribution. Their compact design, durability, and reliability make them essential for today’s power infrastructure projects.

For high-performance ABC cable solutions tailored to your project needs, contact HNBF Power your trusted global manufacturer of advanced overhead conductors and power cables.